For Safer Driving

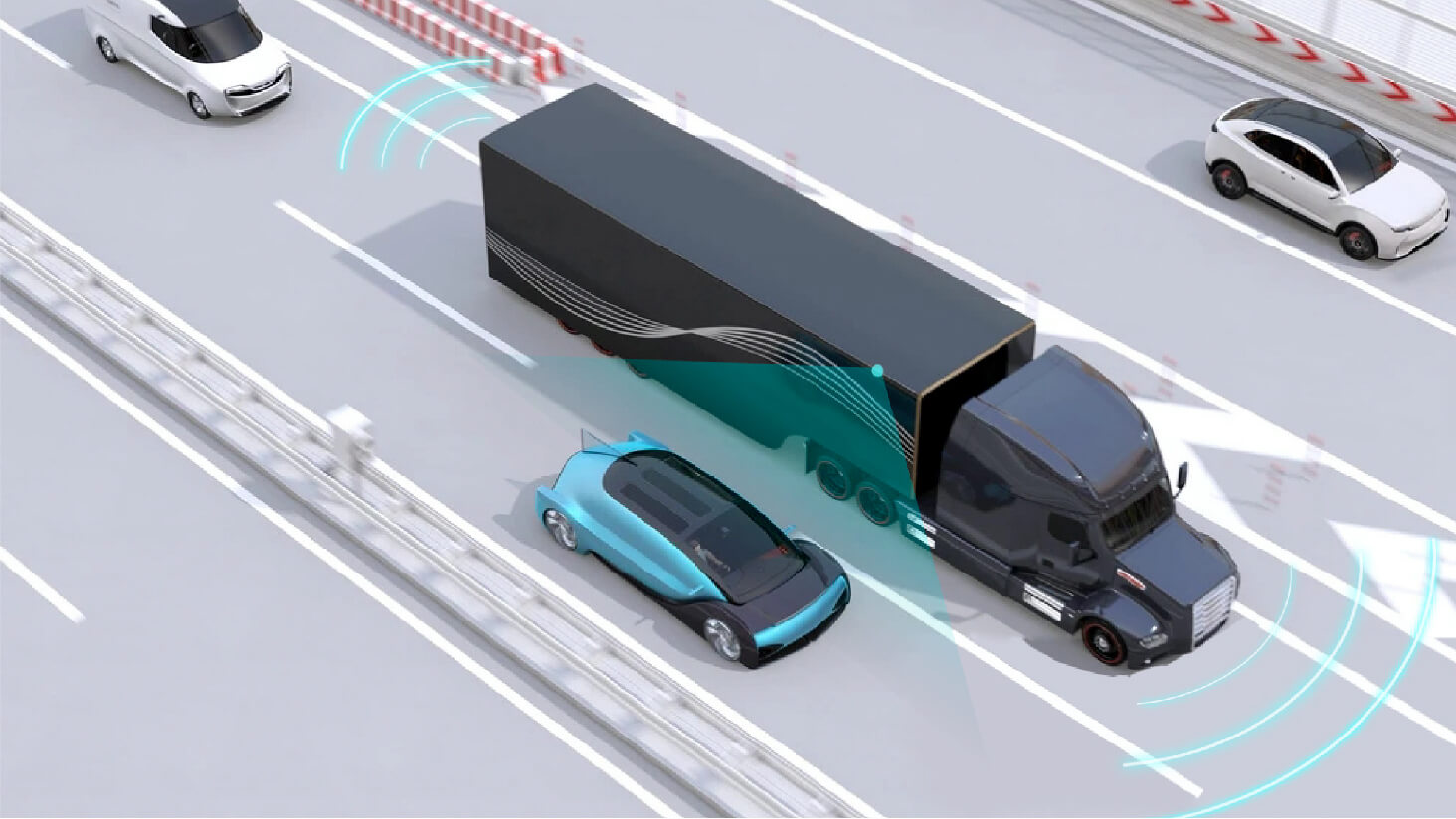

STONKAM CO., LTD. has been focusing on the cutting-edge technology of artificial intelligence (AI) and the layout of intelligent in-vehicle monitoring industry. Creating intelligent in-vehicle monitoring devices and exploring multiple application scenarios of vehicle AI vision solutions, STONKAM aims to empower in-vehicle security with AI and assist in upgrading intelligent and safe driving modes, so as to make driving safer and smarter.

Established in 2003, STONKAM CO., LTD. is a national high-tech enterprise with 22 years of experience in independent researching, developing, global manufacturing and selling of in-vehicle monitoring products and advanced driving assistance products. STONKAM has established intelligent manufacturing bases in Guangzhou, China and Thailand. With over 500 employees, including over 130 R&D engineers, STONKAM is able to quickly tailor for customers' needs and provide with customized OEM & ODM technical service.

Based on technological innovation, STONKAM thoroughly develops in the intelligent in-vehicle monitoring industry and it has successively developed multiple new AI intelligent products certified with hundreds of product patents. Supported by the collaborative manufacturing system between China and Thailand, STONKAM has achieved an export rate of 96%, with its products mainly sold to developed markets such as Europe, the United States, Canada, Australia, and Japan. As a benchmark enterprise in the in-vehicle monitoring industry, STONKAM, through localized production at its Thailand factory and a global logistics network, is committed to providing smart, innovative and high-quality in-vehicle monitoring products and solutions for customers worldwide.

Vehicle's electronic industry experience

Fortune Global 500 designated supplier

Senior engineers

Successful Cases

Independent intellectual property rights

Export countries & region

How to Eliminate Forklift Blind Spots?

In the operation of heavy-duty forklifts, due to the unique structure of the vehicle and the presence of blind spots, traditional rearview mirrors and single-camera systems cannot comprehensively address visibility issues. Forklift operators are prone to mistakes caused by blind spots, which not only affect operational efficiency but may also lead to severe safety incidents. Therefore, overcoming these blind spots and ensuring clear visibility around the forklift is crucial for improving safety and operational efficiency.

View More

STONKAM has passed ISO 26262:2018 ASIL D process certification!

Recently, STONKAM announced that it has successfully passed ISO 26262:2018 Functional Safety ASIL D process certification and received the certificate issued by SGS.

View More

STONKAM has established Intelligent Perception Department!

On May 1, 2025, STONKAM officially announced the establishment of the "Intelligent Perception Department" at its R&D center.

View More